The Versatility and Benefits of Aluminum Jumbo Rolls

Aluminum jumbo rolls are a critical component of various industries, known for their remarkable versatility and wide-ranging applications. From packaging to construction, aluminum jumbo rolls have become an essential material due to their unique properties and benefits. In this article, we’ll delve into the details of aluminum jumbo rolls, their uses, and the advantages they bring to different sectors.

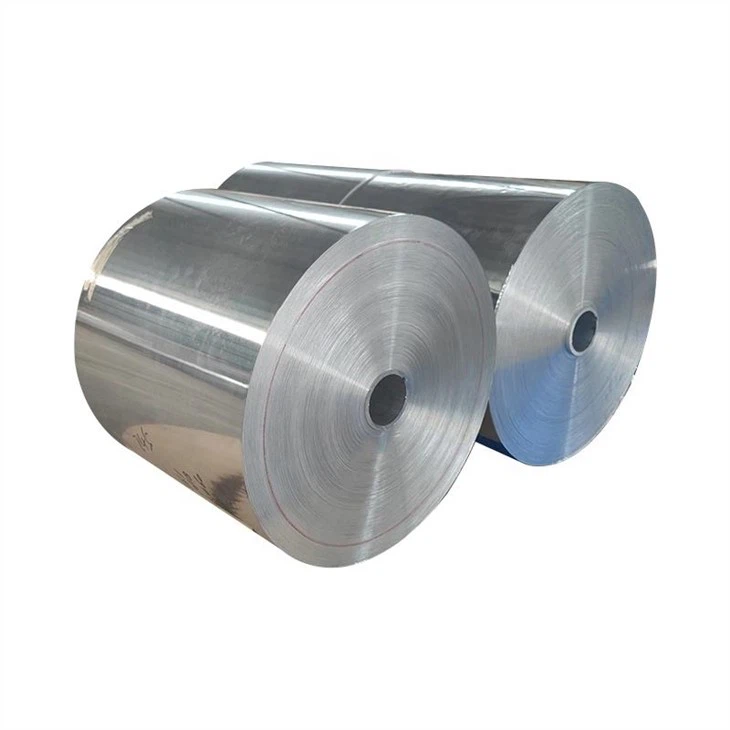

What is an Aluminum Jumbo Roll? An aluminum jumbo roll is a large, continuous sheet of aluminum that is wound onto a core. It serves as the primary material for producing aluminum foil, packaging materials, and other aluminum-based products. The rolls are manufactured through a meticulous process involving melting aluminum ingots, followed by rolling and annealing to achieve the desired thickness and properties.

Applications of Aluminum Jumbo Rolls:

- Packaging Industry: Aluminum jumbo rolls are extensively used in the packaging industry for creating aluminum foil. Its exceptional barrier properties against moisture, light, and contaminants make it ideal for packaging perishable goods, pharmaceuticals, and other sensitive products. The flexibility and heat resistance of aluminum foil further contribute to its popularity in the food industry.

- Construction Sector: In the construction sector, aluminum jumbo rolls find applications in roofing, siding, and insulation. The lightweight nature of aluminum, coupled with its corrosion resistance, makes it an excellent choice for outdoor structures. Its malleability also allows architects and designers to craft intricate shapes and profiles for aesthetically pleasing buildings.

- Electronics Industry: Aluminum jumbo rolls are used in manufacturing components for electronics due to their excellent conductivity. They serve as the base material for printed circuit boards (PCBs), heat sinks, and connectors. The lightweight yet durable nature of aluminum contributes to the overall efficiency and performance of electronic devices.

- Automotive Sector: Aluminum jumbo rolls play a crucial role in the automotive industry, particularly in the production of lightweight vehicle parts. These rolls are transformed into sheets that are used for creating body panels, engine components, and interior parts. The use of aluminum aids in reducing the overall weight of vehicles, leading to improved fuel efficiency.

Advantages of Aluminum Jumbo Rolls:

- Corrosion Resistance: Aluminum possesses a natural oxide layer that provides exceptional corrosion resistance. This property ensures longevity and durability in various applications.

- Lightweight: Being one-third the weight of steel, aluminum jumbo rolls contribute to lightweight product designs, making them suitable for applications where weight reduction is essential.

- Conductivity: Aluminum is an excellent conductor of heat and electricity, making it an ideal choice for industries where efficient heat dissipation and electrical conductivity are required.

- Recyclability: Aluminum is highly recyclable, making it an eco-friendly option. The recycling process requires significantly less energy compared to primary aluminum production.

For more information on aluminum jumbo rolls and their versatile applications, you can This resource provides in-depth insights into the technical specifications and customization options available.

Conclusion: In conclusion, aluminum jumbo rolls have emerged as a cornerstone in various industries, revolutionizing the way products are packaged, constructed, and designed. Their unique combination of properties, including corrosion resistance, lightweight nature, and recyclability, positions them as a sustainable choice for modern applications. As industries continue to innovate and evolve, aluminum jumbo rolls will undoubtedly play an integral role in shaping the future of materials and manufacturing.

Top of Form